Visibly Perfect: Test & Correction Solutions for MicroLED, OLED, and Other Displays

Development in the global display industry has entered a critical period with microOLED, miniLED, and microLED setting off a new wave of technological progress. Because each pixel in these emissive displays is self-illuminating, output differences between pixels may occur, resulting in non-uniform brightness and color across the display. To address this and other visual quality issues, manufacturers can apply scientific photometric imaging systems in R&D and production to measure display output and correct pixel-level values for visibly perfect display quality.

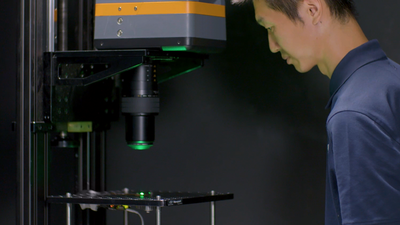

Radiant's portfolio of display test & correction solutions is designed for both R&D and high-throughput inspection applications including pixel-level measurement and calibration (demura). Combining ProMetric® Imaging Colorimeters and Photometers with TrueTest™ Software, these automated visual inspection systems help to increase efficiency, control production costs, and ensure visual quality of consumer electronics displays from large panels to smart devices to virtual & augmented reality headsets.

Watch this video to explore Radiant's solutions for:

- Emissive displays: OLED, miniLED, microLED, microOLED

- Pixel-level measurement and correction (demura)

- Capturing precise luminance & chromaticity values at each subpixel to adjust pixel output and ensure visibly perfect display uniformity at all brightness levels

- Pixel characterization using microscope lenses

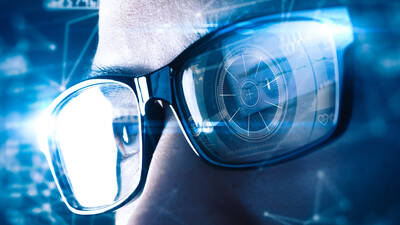

- In-headset measurement for evaluation of AR/VR displays