Particle inspection detects particles and foreign materials on or within transparent components like clear plastic, film, or glass. These particles may cause material to be unsuitable for a subsequent process in manufacturing, or dangerous for application or consumption. Automated visual inspection systems must be specially calibrated to detect and distinguish between particles and their locations. Understanding whether a particle is on the top or bottom of a surface, or embedded within the surface, allows you to adjust operational processes to determine if an inspected material can move on to the next phase of production, if cleaning is required, or if the material must be rejected as scrap.

Radiant’s automated visual inspection solutions employ extremely high-resolution, high-dynamic-range image sensors to detect defects in transparent materials under unpredictable lighting conditions. Minute contrast variations within an imaged area allow our cameras to assess the presence and location of particles and apply defined tolerances to determine the acceptable severity of a particles or number of particle within the material.

Unmatched Camera Resolution and Dynamic Range

Leveraging extremely high-resolution and broad-dynamic-range image sensors, Radiant’s ProMetric® Imaging Photometer or Colorimeter produces unmatched image clarity to detect the smallest particles on or within any substrate. Dynamic range increases the number of grayscale values captured in each image, ensuring that subtle contrast variations are identifiable for fine-detail inspection. The high resolution of Radiant cameras ensures that pixel-sized particles and image noise are clearly discernable. Image noise is minimized through careful systems design and calibration of Radiant’s ProMetric cameras, ensuring images clarity while maintaining inspection speed. With these technical advantages, Radiant inspection systems can detect defects that may go unnoticed by human inspectors, including tiny, light-colored debris on glass or metal surfaces.

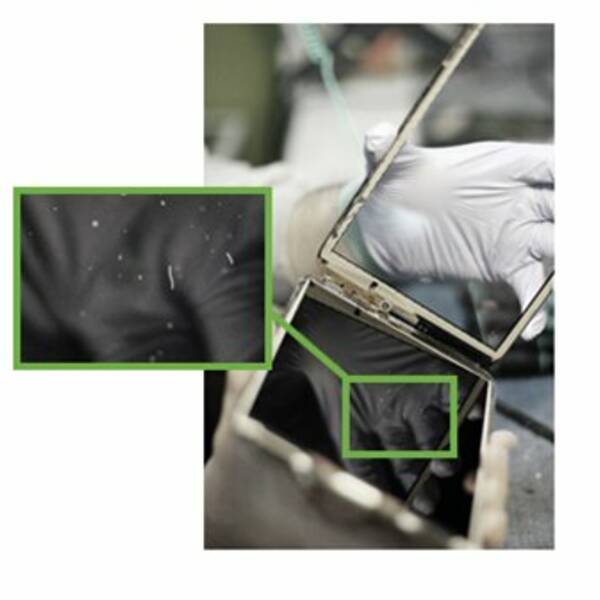

Radiant automated visual inspection software detects particles on this metallic surface that appear invisible to the human eye.

Particles in Consumer Electronics Components

Product quality expectations in consumer electronics are arguably the highest in any industry. Customers demand perfection in their devices and newly-released technologies are routinely reviewed in excruciating detail. A subtle scratch on a laptop surface, or miniscule dust particles behind the glass of a smartphone camera lens, are sufficient cause for product returns and—if widespread—may lead to recalls, costing manufacturers excessive time and money.

To safeguard both your brand and your bottom line, it is imperative to integrate cosmetic surface inspection and particle inspection into quality control operations during production and at final assembly. From a single Radiant camera/software configuration, our solutions employ the complete library of machine vision tools in the TrueTest™ Software platform, performing particle, surface, and assembly inspection routines all at once for total quality control.

Dust below a smartphone camera lens is detected using specialized lighting to reduce glare from specular glass and increase particle contrast.